TwoChain

Bogey Member

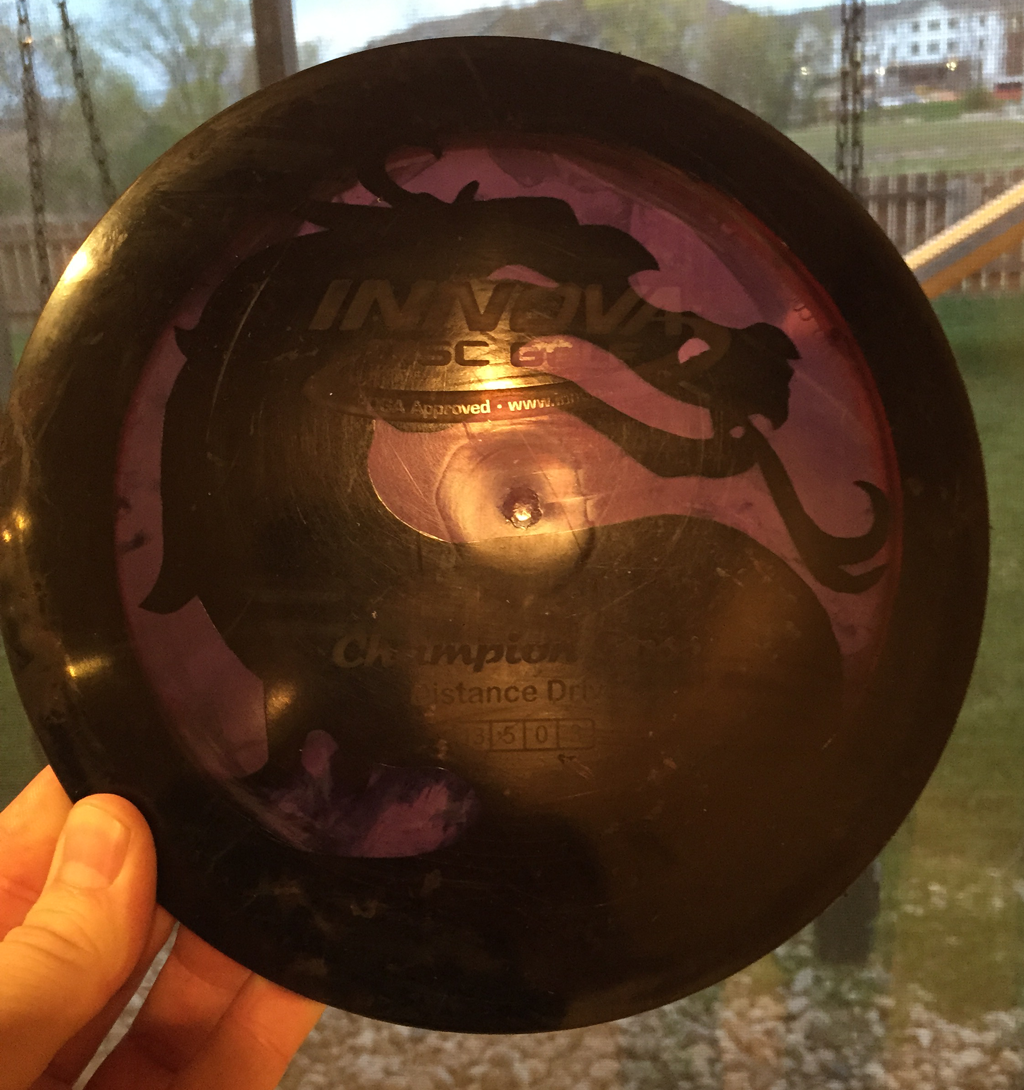

I just started dying some discs. A friend of mine is really good and has been teaching me some stuff. Last night I tried to do a Mortal Kombat logo on my Boss and it could not have gone worse haha.

Using a black water dye and vinyl paper, I had the Mortal Kombat logo perfectly cut out so the dragon was in the clear plastic and the outside ring was to be black. It looked like it was going to be perfect from the back side.

But then! I came back and black dye was leaking on to the back side of the disc. It was maroon champ plastic so I panic and took it out before I wanted to and washed it off. From here it all went down hill and I kept messing with it to make sure the back didn't get black dye on it! During this process of pulling it out of the dye it slipped from my hands and specks of black **** got everywhere. I spent 2 hours cleaning my work area for black spots and ruined some ****ty chairs.

I used about 12oz of dye in a black pan that was a bit bigger than the disc. It seemed like the prefect amount but the disc seemed to sink in a bit more.

This was probably hard for my first die since the black outside of the MK logo went all the way to the edge of the disc making it more likely to get on the back side.

During the panic I washed off the dye and took off the vinyl. There are smudges all between the logo and black areas on the back of the disc. The back of the rim is all mangled too. Every time I turned my back to clean something some how fing dye was behind me or on the fridge or all over places I never even was standing by.

Questions:

1. How can I keep dye from getting on the back of the disc?

2. Do discs tend to float at first then sink?

3. How long should I keep it in the vinyl paper to prevent smudges.

I would like to invent something small where I can lower the disc down with a crank or something and trust it to stay!

Also any suggestions based on what I said would be great. I have using a stencils / cutting and applying vinyl down pretty good.

Using a black water dye and vinyl paper, I had the Mortal Kombat logo perfectly cut out so the dragon was in the clear plastic and the outside ring was to be black. It looked like it was going to be perfect from the back side.

But then! I came back and black dye was leaking on to the back side of the disc. It was maroon champ plastic so I panic and took it out before I wanted to and washed it off. From here it all went down hill and I kept messing with it to make sure the back didn't get black dye on it! During this process of pulling it out of the dye it slipped from my hands and specks of black **** got everywhere. I spent 2 hours cleaning my work area for black spots and ruined some ****ty chairs.

I used about 12oz of dye in a black pan that was a bit bigger than the disc. It seemed like the prefect amount but the disc seemed to sink in a bit more.

This was probably hard for my first die since the black outside of the MK logo went all the way to the edge of the disc making it more likely to get on the back side.

During the panic I washed off the dye and took off the vinyl. There are smudges all between the logo and black areas on the back of the disc. The back of the rim is all mangled too. Every time I turned my back to clean something some how fing dye was behind me or on the fridge or all over places I never even was standing by.

Questions:

1. How can I keep dye from getting on the back of the disc?

2. Do discs tend to float at first then sink?

3. How long should I keep it in the vinyl paper to prevent smudges.

I would like to invent something small where I can lower the disc down with a crank or something and trust it to stay!

Also any suggestions based on what I said would be great. I have using a stencils / cutting and applying vinyl down pretty good.

Last edited: